Making accurate biometric wearables that scale

Let’s talk about how making accurate biometric wearables that scale.

Here again the phrase “you are only as strong as your weakest link” is applicable, because even if you can get the technology to work in a prototype, there are many other aspects to getting a product to market at scale that works as advertised.

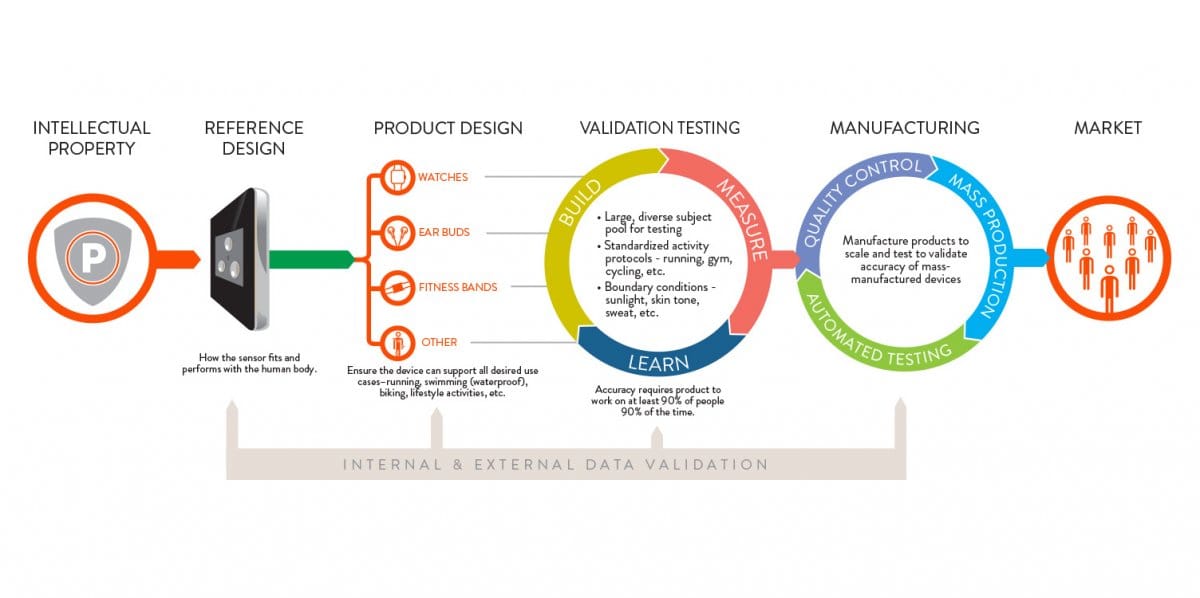

The diagram below shows the “behind the scenes” work that’s absolutely critical to making successful biometric wearables. Each of these steps are links in the chain that must be done right or your product risks ending up in the sock drawer.

Intellectual Property

There is a significant amount of intellectual property that has already been established in the wearables market, particularly for ear and wrist-based devices. In particular, IP around fitness tracking, biometrics, and data analysis are fairly robust at this point.  Any company bringing a new product to market needs to understand that IP landscape and how their designs can benefit from the existing IP to build off existing inventions. There is, of course, a risk management aspect to this as well as you’re starting to see more companies defend their intellectual property related to wearables in the market.

Any company bringing a new product to market needs to understand that IP landscape and how their designs can benefit from the existing IP to build off existing inventions. There is, of course, a risk management aspect to this as well as you’re starting to see more companies defend their intellectual property related to wearables in the market.

Reference Designs

Reference designs are a great way to get a head start in a wearables project. It’s much easier and more effective to start from a reference design that works than design from scratch. However, you need to ensure the reference designs work before getting too far down the design path. Reference designs that have been proved to be accurate have already worked out many of the design challenges that you’ll face designing from scratch. This is particularly true in biometric wearables, where numerous optomechanical and physical design rules must be followed to ensure accuracy, comfort, and effectiveness of these devices.

Reference designs are a great way to get a head start in a wearables project. It’s much easier and more effective to start from a reference design that works than design from scratch. However, you need to ensure the reference designs work before getting too far down the design path. Reference designs that have been proved to be accurate have already worked out many of the design challenges that you’ll face designing from scratch. This is particularly true in biometric wearables, where numerous optomechanical and physical design rules must be followed to ensure accuracy, comfort, and effectiveness of these devices.

Product Design

With that said, the product managers at wearables device makers know their customers better than anyone in the world. They typically want a design that fits with their brand and their intended use case, which makes design customization a very common practice in biometric wearables. The most important part of designing a biometric wearable is managing the tradeoffs in size, comfort and accuracy in the device. You need to ensure any customizations made don’t impact accuracy negatively, while maintaining look, feel, and comfort in supporting the intended use cases.

With that said, the product managers at wearables device makers know their customers better than anyone in the world. They typically want a design that fits with their brand and their intended use case, which makes design customization a very common practice in biometric wearables. The most important part of designing a biometric wearable is managing the tradeoffs in size, comfort and accuracy in the device. You need to ensure any customizations made don’t impact accuracy negatively, while maintaining look, feel, and comfort in supporting the intended use cases.

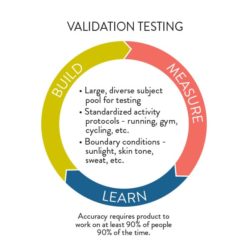

Validation testing

This is the step in the process that typically gets under-resourced or sometimes completely overlooked by consumer electronics brands. Although consumer electronics brands are quite familiar with testing how consumers use digital devices, most brands have little experience understanding how consumers wear digital devices, particularly biometric wearables. Moreover, even fewer brands understand the relationship between wearability and accuracy when it comes to body-sensing wearables. The big mistake we see brands make is applying traditional consumer electronics human subject testing, such as how people use keyboards or smartphones, to wearables. However, this doesn’t account for the huge variability in human physiology.

This is the step in the process that typically gets under-resourced or sometimes completely overlooked by consumer electronics brands. Although consumer electronics brands are quite familiar with testing how consumers use digital devices, most brands have little experience understanding how consumers wear digital devices, particularly biometric wearables. Moreover, even fewer brands understand the relationship between wearability and accuracy when it comes to body-sensing wearables. The big mistake we see brands make is applying traditional consumer electronics human subject testing, such as how people use keyboards or smartphones, to wearables. However, this doesn’t account for the huge variability in human physiology.

Biometric wearables have to work on wide variety of people doing a wide variety of things. In fact, the Valencell standard is that any PerformTek-branded products should work on 90% of people, 90% of the time.

Making this happen requires a Build, Measure, Learn process:

- Build: prototypes based on reference designs and customizations to meet customer and brand requirements

- Measure: rigorous and thorough testing on wearable prototypes under activity protocols that match the intended use case. For example, if you are building a device for triathletes, swimming, biking and running tests in various conditions are all minimum requirements. You also need a large, diverse subject pool for testing people of all shapes, sizes, colors, and fitness levels.

- Learn: analyze the data, learn the breaking points of the device, and how to improve on the current prototype. Valencell instructs its partners to test each prototype on at least 20 people, of diverse physical habitus, before making any conclusions on changes to be made to the prototype.

And then repeat the process until you have a device that meets your customers’ expectations.

Manufacturing

Once you get to a great design that works, now you have to make sure it’s manufactured in a way that is scalable without impacting the integrity and accuracy of the device. This requires quality control and automated testing to scale:

Once you get to a great design that works, now you have to make sure it’s manufactured in a way that is scalable without impacting the integrity and accuracy of the device. This requires quality control and automated testing to scale:

- Quality Control (QC) : understand where the device is being manufactured, what are their skills and strengths, and whether or not they ever produced a biometric wearable before. At Valencell, we have an ecosystem of manufacturing partners who have passed a rigorous certification process to ensure quality, repeatability and worker safety in the product manufacturing and quality control process.

- Automated testing: a key part of maintaining quality at scale in biometric wearables is testing products as they come off the production line. Valencell has developed an automated testing tool available to all our licensees that streamlines the testing process, while ensuring quality and accuracy are maintained.

Market

Once you have a high-quality, accurate biometric wearable rolling off the production lines, the marketing folks take over. This topic could be an entire post in itself, but here are a couple of things we’ve seen that work well:

Once you have a high-quality, accurate biometric wearable rolling off the production lines, the marketing folks take over. This topic could be an entire post in itself, but here are a couple of things we’ve seen that work well:

- The marketing research should start at the beginning of the product concepting phase, assuring that the product to be developed hits the target market with the right use case. A “soft launch” of the product can help generate market feedback for quickly adapting product features and product messaging.

- Set the right expectations. Make sure the expectations your marketing sets in your customers’ minds can actually be supported by the device. This is especially true when advertising the accuracy of wearable biometric sensors. We’ve seen too many wearable device companies get into trouble when their advertisements show high-intensity activities, but when you read the fine print of the user guide (or try to use the device like the commercials) you find a big disconnect.

- Independent research. Support your device marketing with data and validation, preferably with 3rd party, independent validation of the device’s performance. Here are some examples: https://valencell.com/white-papers

Getting accurate biometric wearables to market is a complex, multi-faceted process, but it can be done well when you focus on the steps outlined in this blog series. We’d welcome your comments below or reach out to us at [email protected] to discuss directly.